The type of technology used in supply chains is changing rapidly, and shippers have varying levels of sophistication and needs surrounding technology adoption, configuration and implementation. However, it is clear that technology is serving as a competitive differentiator and boosting supply chain performance.

Nearly all respondents in the 2024 Annual Third-Party Logistics Study— 87% of shippers and 94% of 3PLs — agreed that adopting emerging technology is critical to future growth and overall success. The study found that the main reason for investing in technology is to improve process efficiency and productivity followed by reducing operational costs and improving visibility across the supply chain.

Andy Moses, senior vice president of solutions and sales strategy at Penske Logistics, said it is essential for technology to solve specific problems. “You don’t want to waste a shipper’s time on a shiny new object if there isn’t a practical application short- or near-term,” he added.

The 3 Main Areas of Focus

Three key areas technology addresses are supply chain optimization, resiliency and efficiency.

1. Optimizing Supply Chain Performance

The stresses impacting logistics networks today are significantly different and more challenging than five years ago, and overall improvement is a priority for supply chain professionals. Data, advanced analytics and intelligence are some of the most important emerging technology areas shippers and their logistics providers are using to optimize performance.

The Gartner for Supply Chain report The Top Eight Supply Chain Technology Trends found that the majority of supply chain professionals taking part in the survey said their organization is improving technologies to support end-to-end processes and has benefited from improved data rationalization and process integration capability.

Shippers and their logistics providers can optimize supply chain performance in multiple ways:

Network Design

A network’s overall design directly correlates to its efficiency. Modeling software can draw on shippers’ supply chain data — such as varying levels of inventories, costs, modes of transportation and sourcing locations — to model the most efficient scenarios. Shippers and logistics providers can also use data to pinpoint the weakest links in the supply chain and establish ample workarounds in anticipation of disruptions.

Real-Time Decision Making

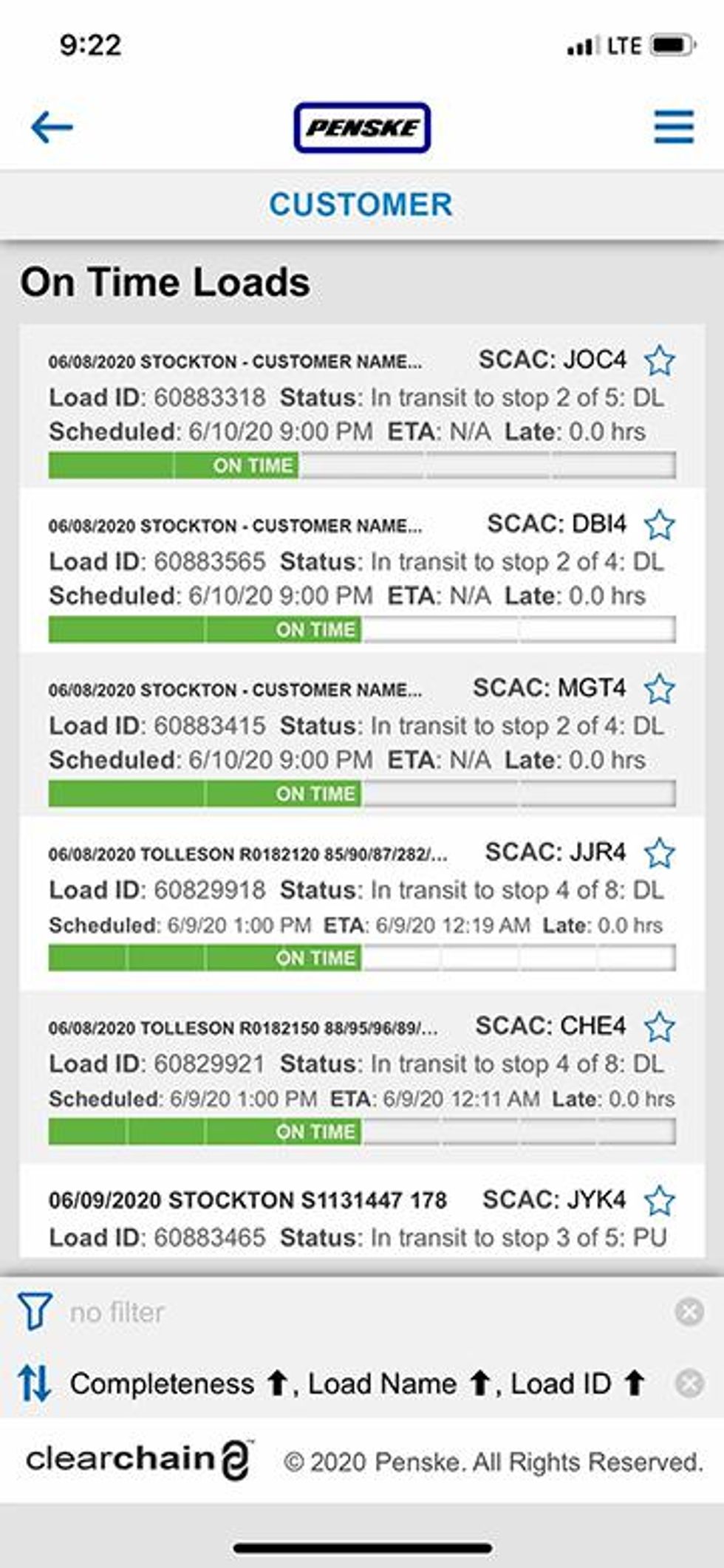

Supply chain technology can leverage real-time data and analytics to provide insights into performance metrics, inventory levels, delays and potential disruptions. This allows businesses to make informed decisions, identify areas for improvement and proactively respond to shifting conditions. The Council of Supply Chain Management’s 2023 State of Logistics Report found that 3PLs are nearly twice as likely to provide real-time data on items in transit compared to their shipper counterparts.

Automation

Artificial intelligence and machine learning can automate tasks and decision-making that have historically relied on human action. Shippers participating in the 2024 Annual Third-Party Logistics Study reported that they see the most value in automating supply planning, demand forecasting and inventory management. Additionally, almost half of respondents said they have plans to automate decisions, with 25% of shippers and 27% of 3PLs saying they’ve already started to automate low-risk decisions.

2. Resiliency in the Face of Supply Chain Disruptions

Resiliency in the supply chain has become a cornerstone principle as shippers work to keep up with consumer purchasing patterns, global unrest, transportation challenges and potential supplier shortages. Increased visibility, greater access to data, artificial intelligence and machine learning are enabling shippers to see what is happening across their supply chain at any time, helping to reduce and mitigate disruptions.

“With disruptions, there is an inverse relationship between when you become aware of the disruption and when you react, which impacts the availability and cost of the solution. The bigger of a surprise and the shorter amount of time you have, the more it will impact you,” Moses said.

When there is a risk of disruption, real-time visibility allows for a rapid response and enables shippers to make data-driven decisions. For example, systems can overlay weather patterns and traffic information to identify potential disruptions, allowing shippers to pull materials ahead or reroute shipments.

Among respondents in the 2024 Annual Third-Party Logistics Study, 74% of 3PLs indicated that using predictive analytics — the leveraging of historical data, statistical algorithms and machine learning — had the greatest potential for their organization. Additionally, the Top Eight Supply Chain Technology Trends report found that through 2024, 50% of supply chain organizations will invest in applications that support AI and advanced analytics capabilities.

“It is clear that this merger of man and machine is going to do great things for the business community,” Moses said. “People can’t sift through millions of data points like sophisticated tech algorithms can. On the other hand, the tech itself can’t make a final determination. It is figuring out if there is a problem to be solved or not.”

Predictive analytics assesses risk factors that may impact the supply chain. Early identification of potential risks allows companies to develop contingency plans, diversify suppliers and make informed decisions to mitigate the impact of disruptions on the supply chain.

Visibility and analytics also enable better decision-making around inventory, which is expensive. The 2023 State of Logistics Report found that $759 billion of the $2.3 trillion in business logistics cost is now associated with inventory management. The goal is to hold as little inventory as possible, but enough so it stays in stock.

Visibility allows shippers to source critical stock from the right locations, make data-driven decisions about moving products, and avoid out-of-stock items. Similarly, predictive analytics can improve demand forecasting and inventory management.

3. Increasing Efficiency

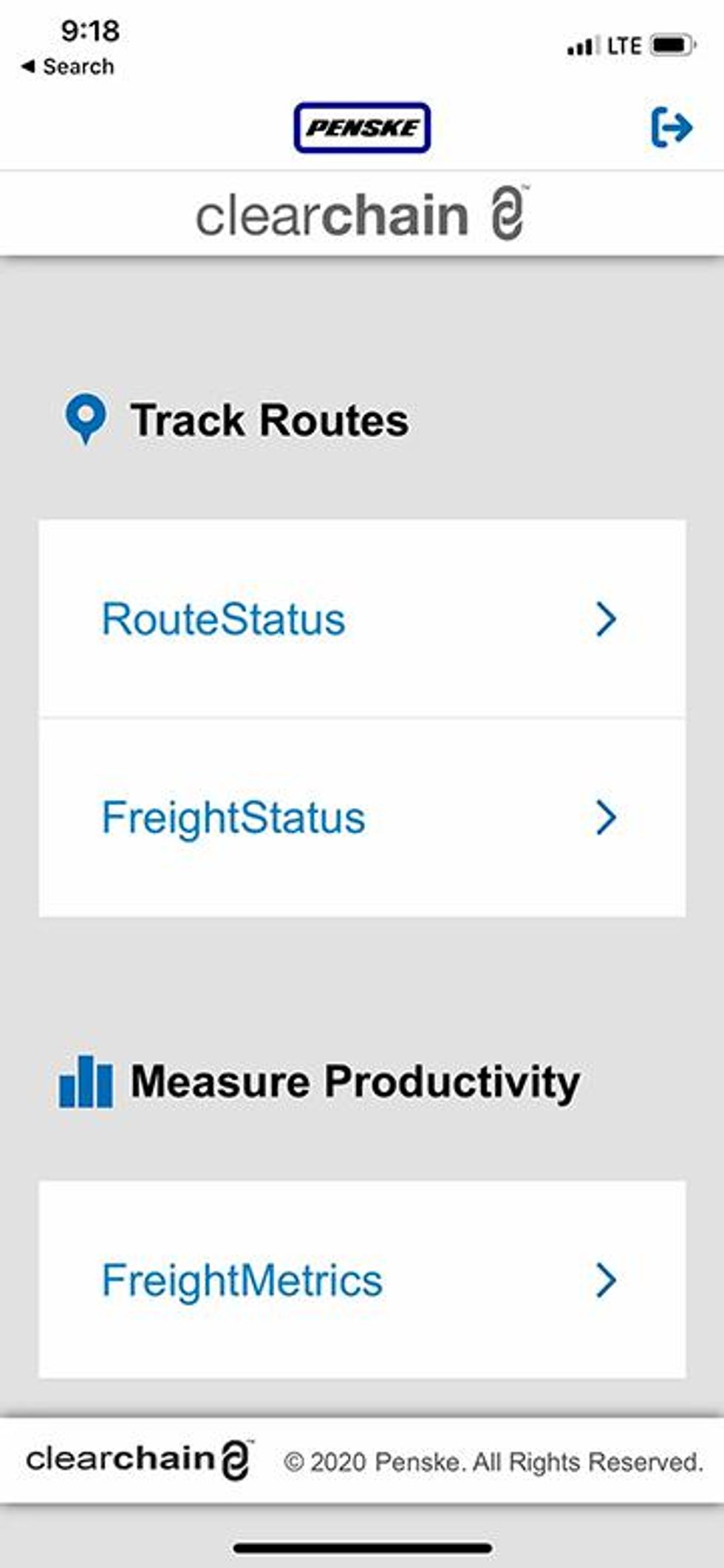

Optimizing networks, streamlining processes, increasing visibility and utilizing data to make critical business decisions all contribute to increased efficiency. Solutions like supply chain control towers that combine people, processes, data and technology into a single, panoramic view of supply chain operations can streamline communication and uncover opportunities for improvement.

On a tactical level, data can drive strategic decisions on a weekly or monthly basis. For example, greater visibility could show there are two shipments of the same items scheduled just two days apart. Systems that allow logistics providers to run what-if scenarios can help shippers determine what would happen if they held the first order.

Information can also be used more granularly for increased efficiency. Route optimization (the efficient sequencing of stops) and dynamic routing (changing delivery schedules on the fly based on the current conditions) reduce transportation costs, enhance delivery efficiency and minimize delays, contributing to a more reliable and cost-effective supply chain.

Efficiency improvements also contribute to supply chain sustainability. The greenest mile is one that isn’t taken. Route and network optimization improves utilization, eliminating miles, decreasing fuel consumption and removing carbon emissions. Software can also help companies match backhaul capacity with available loads, filling miles that otherwise would have been empty.

In today’s operating environment, stakeholders, including consumers, seek specific details on how companies reduce their carbon footprint; technology can help shippers and their logistics providers measure and quantify improvements.

Finding the Right Solutions

As consumer expectations and business demands increase, the importance of supply chain technology will only intensify. Leveraging the latest supply chain technologies creates a more agile, responsive and efficient supply chain, reduces costs and improves service. It is essential to utilize solutions that provide value, and supply chain leaders need to thoroughly identify, research and evaluate solutions.

Moses said 3PLs get to see technology play out across multiple industry verticals, which gives them valuable insights. “There are many different emerging technologies in the space. What customers really value is someone knowledgeable across the spectrum that can point them toward something commercially viable today versus something that may have promise two to three years from now,” he explained.